-

-

Address

Kolhapur - 416236

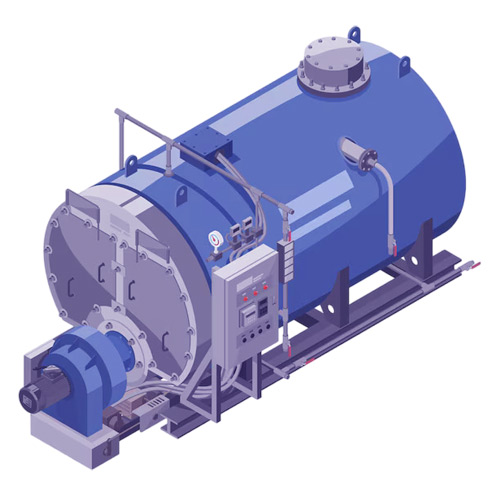

Gas Fired Boilers

Radiant Boilers Private Limited is a prominent manufacturer and supplier of a diverse range of boilers and industrial heating solutions including smoke tube boilers,twin furnace boilers,oil and gas fired boilers, industrial boilers such as combo pack and membrane boilers as well as a variety of boiler accessories and spares, catering to various industry needs. Committed to innovation and sustainability, our vision is to become a global leader in manufacturing and developing boilers and advanced heating solutions, recognized for best quality and advanced technology tailored to meet diverse industrial needs.

Gas fired boilers are widely recognized for their efficiency and reliability in generating heat for various applications. These boilers operate by combusting natural gas or propane, producing hot gases that heat water or steam within the boiler system. The combustion process typically involves a burner that mixes fuel with air, igniting it to produce heat. The heat generated is transferred to the water circulating through the boiler which can then be utilized for heating spaces, water or powering industrial processes. The design of gas fired boilers can vary significantly including options such as fire tube and water tube configurations, each optimized for diverse functional demands.

The construction of gas fired boilers involves several key materials that ensure durability and efficiency.Carbon steel is commonly used for the boiler shell and internal components due to its strength and affordability. It is often treated with protective coatings to enhance its resistance to corrosion, especially in high temperature environments.Stainless steel is another critical material utilized in gas fired boilers because of its excellent corrosion resistance and thermal stability, making it ideal for components exposed to harsh conditions.

Alloy steels, particularly those containing chromium and molybdenum, are employed in areas requiring high strength and resistance to creep at elevated temperatures, such as super heater tubes. Additionally, refractory materials are used to line the combustion chamber and other high temperature areas of the boiler. These materials can withstand extreme heat while minimizing heat loss. Common refractory materials such as alumina,silica and various insulating compounds help maintain thermal efficiency.

- Adaptability: These boilers can be used for both heating water and steam generation, making them suitable for a wide range of applications in residential, commercial, and industrial settings.

- Low Noise Levels: Gas-fired boilers operate quietly compared to other heating systems, contributing to a more comfortable environment without disruptive noise.

- Reliability: With fewer moving parts and a simpler design, gas-fired boilers tend to require less maintenance and have a longer operational lifespan, ensuring consistent performance over a longer period.

- Cost-Effective Operation: Although the initial installation cost may be higher, the long-term savings on fuel costs and maintenance make gas-fired boilers a cost-effective heating solution.

- Environmental Friendliness: These boilers produce fewer emissions compared to oil or coal-fired systems, contributing to improved air quality and a smaller climate impact.

- Quick Heating: Gas-fired boilers heat up rapidly, providing immediate hot water or steam, which is particularly beneficial in residential and commercial settings where quick response times are essential.

- Mining Operations: In mining, gas-fired boilers generate steam for ore processing and power generation at remote sites, supporting various functional needs in harsh environments.

- Oil Refineries: Gas-fired boilers are integral to oil refineries, providing the high-temperature steam needed for distillation processes and maintaining specific temperatures during refining operations.

- Healthcare Facilities: In hospitals and healthcare facilities, gas-fired boilers supply steam for sterilization of equipment and heating systems, ensuring a safe and comfortable environment for patients and staff.

- Paper Industry: Gas-fired boilers are used to generate steam for cooking wood chips and drying paper products, facilitating various stages of paper manufacturing.

- District Heating Systems: These boilers can be integrated into district heating systems, supplying steam or hot water to multiple buildings from a centralized source, enhancing energy efficiency in urban areas.

- Food and Beverage Processing: These boilers play a critical role in food processing facilities, supplying steam for cooking, sterilization, and heating water used in production lines to ensure hygiene.

- Energy Generation: Gas-fired boilers are utilized in power generation to produce steam that drives turbines, contributing to electricity generation for both grid supply and on-site consumption.